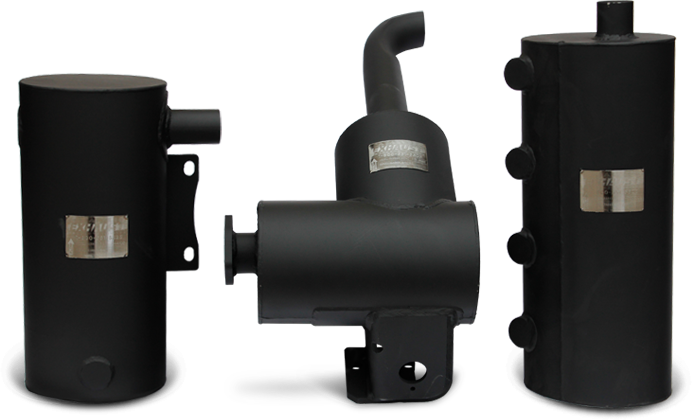

Purifier Mufflers

Summary

With over 25 years in the emission control industry, Catalytic Exhaust Products has amassed over 10,000 muffler designs. Our Purifier mufflers are designed to replace the Original Equipment Manufacturer (OEM) muffler system while maintaining the same if not better sound attenuation. Purifier mufflers are the most desirable option for a large variety of applications available for both diesel and gas engines. Purifier mufflers are designed to receive the maximum amount of exhaust heat energy in order to operate at high efficiency (90%+ emission reductions). The difficulty and time required for installing a custom purifier muffler is minimal, simply remove the OEM stock muffler and replace our purifier muffler. Overall a purifier muffler will provide the most efficient reduction, the easiest installation, the least engine downtime and the most reliable operation.

Catalytic Exhaust Products also supplies standard muffler designs without a catalytic core. Our mufflers can be built with Stainless Steel, Mild Steel or Aluminized Steel. Call us today, for more information!

Common Applications

| Allen | Bobcat | Bomag |

| Gehl | Genie | Gradall |

| Ingersoll | JCB | JLG |

| Briggs and Straton | Grove | John Deere |

| Case | Hatz | Kawaski |

| Caterpillar | Hitachi | Kobelco |

| Clark | Honda | Kohler |

| Compare | Hyster | Komatsu |

| Deutz | Husqvarna | Kubota |

| Doosan | I.H.I | Miller |

Note: Common exhaust purifier mufflers are kept in stock and can be shipped out same day.

The Major Catalytic Oxidation Reactions which Occur are:

For Oxides of Nitrogen

NOx + CO → N2 + CO2

NOx + H2→ H2O + N2

For Carbon Monoxide

CO + O2→ H2O + N2

For Hydrocarbons

HC + O2→ CO2 + H2O

Features

High Efficiency "Tortuous" Flowpath Catalytic Core

Our Purifier Mufflers feature a unique “tortuous” flowpath catalytic core, incorporating a curved mixed flow cell design. This takes advantage of the physical properties of harmful pollutants, increasing contact with the catalytic core surface. By promoting the contact between harmful pollutants and the catalytic core the “tortuous” flowpath core design is superior in reducing harmful pollutants produced by the engine.

High Quality Catalytic Coating

Our Purifier Mufflers feature a high quality platinum-rhodium coating, which is very carefully distributed upon a uniform high porosity wash coat. The high quality coating provides long life, increases cold start performance, and enhances thermal durability of the catalyst. The net results are high efficiency catalytic reactions, which lead to very low exhaust pollutants.

Superior Thermal and Physical Strength

Our Purifier Mufflers are constructed of high temperature tolerant, corrosion resistant, stainless steel alloys. Thick stainless steel alloy retainers are used to provide support and stability for the inlet and outlet faces of the metallic core. Our Purifier/Mufflers use inlet flow diverters for even exhaust flow distribution and improved operating efficiency.

Low Exhaust Gas Restriction

Our Purifier Mufflers feature high strength, ultra-thin metallic core walls. These allow a minimal exhaust gas restriction during operation, even under high load/ speed operating conditions. The exhaust gas backpressure restriction will be in the order of 6.0” to 9.0” water gauge at full load.

Easy Installation

Our Purifier Mufflers are a direct fit muffler replacement designed for ease of installation. Simply remove your current muffler and install the Purifier Muffler directly in place of the old one.